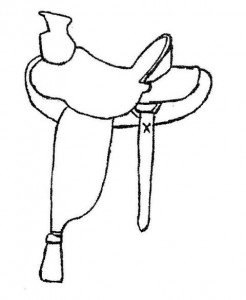

Do you want to know how to make a 1/9th inch scale western Wade ranch saddle?

If so, you are in the right place. Continue reading.

Introduction

Bob Jones Tiny Saddle Maker and Author

Welcome. Let me introduce myself.

My name is Bob Jones. I am a tiny saddle maker.

I make the tiny 3-inch replica western Wade ranch saddles with leather, apple or maple wood for the stirrups and metal wire for the cinch rings, shoulder dees and saddle conchos.

All these pieces and more are fitted to a saddle measuring a total of 3 inches in length.

Would you like to learn how to make your tiny 3-inch Wade saddle?

Experience

In 2007 at the age of 62, I began making tiny saddles. I continue to make saddles today.

One recurring point of frustration was attempting to make a saddle without a blueprint to follow. The hit or miss (also known as trial and error) method did not work. I got lost in the building process way too many times.

I made other mistakes too.

- Used deer skin because it was soft but deer skin also stretches. Not a good thing when fitting two separate pieces together.

- Also, used the wrong kind of glue on leather.

- And, instead of a leather cutting blade, a medium and large pair of household scissors were used to cut the deer skin. Both pairs were damaged beyond repair.

Have you had similar experiences?

<script async data-uid=”749df80d4f” src=”https://patient-fire-1204.ck.page/749df80d4f/index.js”></script>

E-guide is a blueprint

After I realized I needed a blueprint to follow, I organized my saddle making notes and wrote an e-guide titled “The Art of Making Tiny 3-inch Western Wade Ranch Saddles.”

The e-guide was not written within 60 or 90 days after I began saddle making. No, the time was more like 4 plus years before I began writing.

During the four plus years,

- I researched saddle making;

- studied saddle makers via saddle journal subscriptions;

- saddle makers web sites; and,

- purchased saddle making books and CDs.

Next, I modified the full size saddle making process to the tiny 3-inch saddle based on the 1/9th inch scale.

I tested the process by making a tiny saddle and the process worked. Then, I wrote the e-guide.

Today the process evolves by fine tuning to make the building process work better.

I wrote the e-guide to help you make or build a tiny saddle. Specifically, a tiny western Wade ranch saddle.

E-guide details

Included in the e-guide are 27 chapters on saddle topics plus a chapter with 18 saddle patterns. All of the chapters help you make a tiny Wade saddle with detailed step by step instructions in sequential order.

This means each step is numbered within each chapter. And that means no getting lost in the building process.

Patterns

The 18 saddle patterns are traced individually from the e-guide’s paper pattern onto a thin (1/16 or 1/32 inch thick) piece of plywood. Cut out the plywood pattern and sand the edge to a smooth finish to make a permanent pattern. Use the plywood pattern to trace onto the leather and cut out the leather tracing.

For example—use one pattern to create a matched pair of fenders by turning the pattern over from side to side—to the right or to the left.

After tracing the pattern onto the leather, cut out the patterns from the leather. Place one fender on the top of the other and trim to match creating a pair of matched fenders.

The 27 chapters and the 18 saddle patterns gives you a blueprint to follow to make your saddle.

Review the listing for some of the chapters and the patterns in the home page section.

The blueprint and you

The e-guide provides the blueprint. You provide the effort to practice and to build.

The e-guide and your effort means you make tiny saddles-making you a tiny saddle maker.

Well, you are a tiny saddle maker. Let’s make a tiny Wade saddle.

<script async data-uid=”749df80d4f” src=”https://patient-fire-1204.ck.page/749df80d4f/index.js”></script>